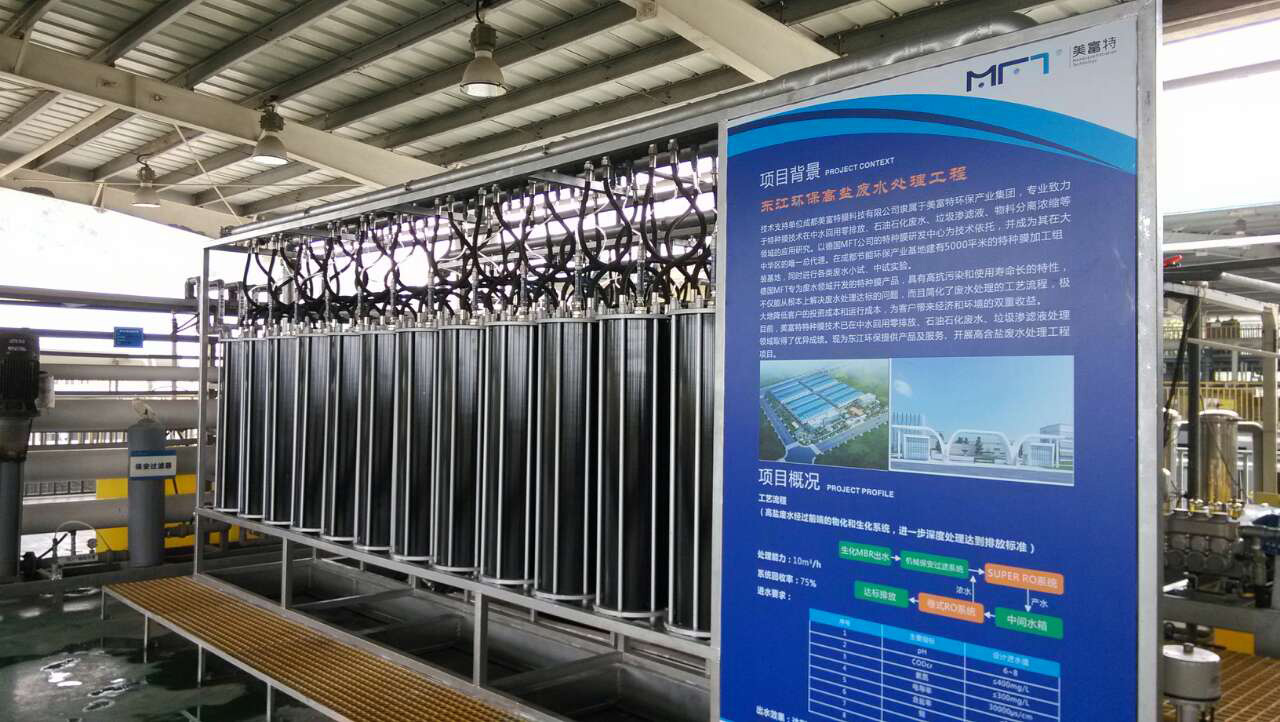

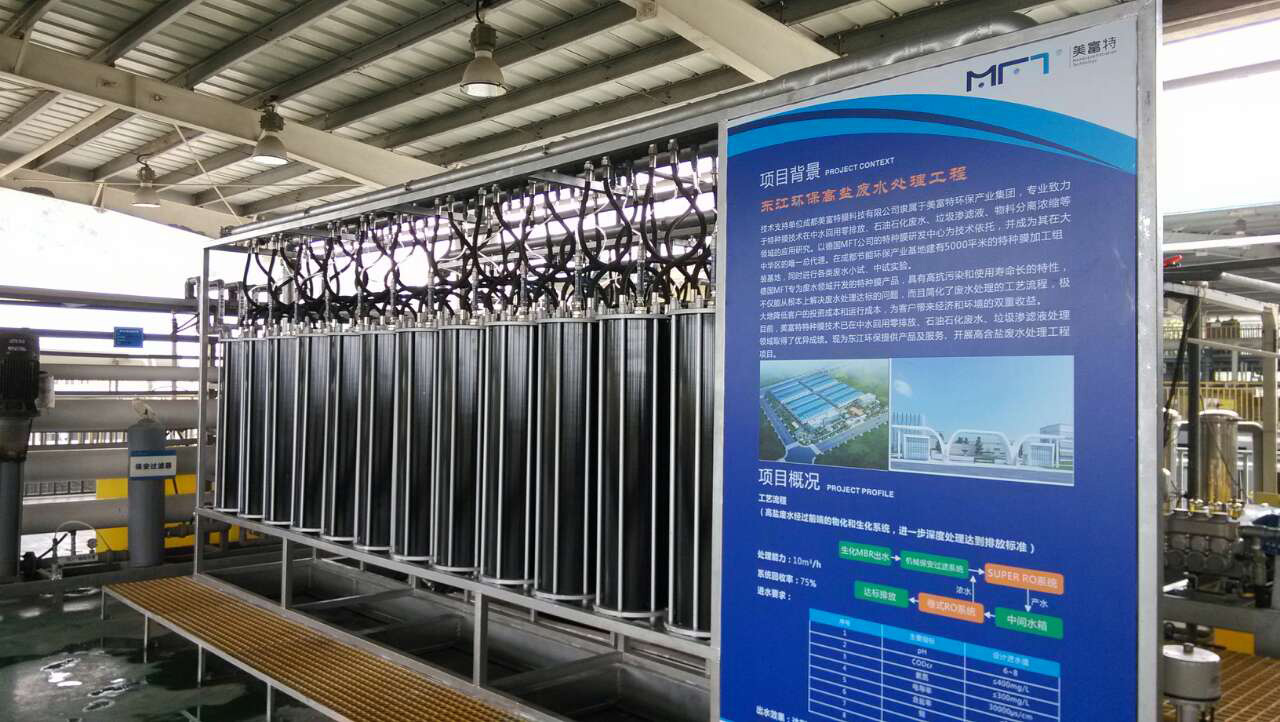

—The First Zero-Emission Electroplating Wastewater Park Approved in China

The Sino-German Metal Eco-City is one of the fifteen cooperative projects signed by Premier Li Keqiang and former German Chancellor Angela Merkel. This project is located in Jieyang City, Guangdong Province, known as the "Hardware Capital of China", and is China's first zero-discharge electroplating industrial park. It serves as an important platform for Sino-German cooperation, a demonstration area for the concentration and intensive development of traditional advantageous industries, promoting clean production and circular economy.

The project was designed to handle a capacity of 5,000 tons per day. As the earliest electroplating wastewater zero-discharge park in the country, there were not many precedents to follow during its design, so it adopted a traditional "physical + biological (A²/O + MBR) + multi-stage multi-segment spiral membrane + evaporation" process. During actual operation, there was a significant gap between the production capacity and the designed zero-discharge capacity, resulting in relatively high overall operation and maintenance costs, which constrained the park's green and sustainable development. The park's management has been actively seeking a stable and reliable zero-discharge renovation solution.

After conducting numerous research experiments and analytical demonstrations within the park, Meifeng Environment proposed an economical and reliable solution based on over twenty years of experience in wastewater treatment technology research and application, leading to a collaboration between the two parties. Meifeng Environment specifically improved the configuration of physical and biological treatment stages to ensure the stability of pre-treatment. Simultaneously, it replaced the original membranes with Mefute's special membrane products, the high-flux flat membrane DMBR and SUPER DT-RO, which are distinguished from traditional membranes in their applications due to their high throughput, high resistance to fouling, and high concentration capabilities. Their use shortened the concentration process of the membrane system, increased the stability of the entire system's operation, and reduced the volume of concentrate by more than 25% compared to before the renovation, significantly reducing the operational costs of the project.

Inlet Water Quality Indicators

Type of Wastewater | Flow Rate | pH | Conductivity | Ni | Zn | Cu | Cr | Cr6+ |

Nickel-containing | 400 m³/d | 3~6 | ≤7500 μS/cm | ≤1443 mg/L | ≤26 mg/L | ≤10 mg/L | ≤18 mg/L | ≤2.0 mg/L |

Chromium-containing | 480 m³/d | 3~6 | ≤4600 μS/cm | ≤110 mg/L | ≤267 mg/L | ≤10 mg/L | ≤840 mg/L | Total Cr controlled |

Zinc-containing | 250 m³/d | 4~12 | ≤13200 μS/cm | ≤10 mg/L | ≤500 mg/L | ≤10 mg/L | ≤10 mg/L | ≤2.0 mg/L |

Cyanide-containing | 80 m³/d | 8~11.2 | ≤6200 μS/cm | ≤12 mg/L | ≤40 mg/L | ≤783 mg/L | ≤10 mg/L | ≤2.0 mg/L |

Pre-treatment | 505 m³/d | 2~11 | ≤12000 μS/cm | ≤15 mg/L | ≤456 mg/L | ≤10 mg/L | ≤10 mg/L | ≤2.0 mg/L |

Comprehensive | 185 m³/d | 2.0~10 | ≤6000 μS/cm | ≤17 mg/L | ≤36 mg/L | ≤1000 mg/L | ≤10 mg/L | ≤2.0 mg/L |

Complex | 70 m³/d | 2.2~8 | ≤5000 μS/cm | ≤50 mg/L | ≤50 mg/L | ≤200 mg/L | ≤10 mg/L | ≤2.0 mg/L |

Mixed discharge | 30 m³/d | 4~10 | ≤8000 μS/cm | ≤100 mg/L | ≤50 mg/L | ≤100 mg/L | ≤100 mg/L | Total Cr controlled |

Outlet Water Quality Indicators

Reclaimed Water Standard | Reclaimed Water Standard | Reclaimed Water Standard | Reclaimed Water Standard |

No. | Test Item | Unit | Standard |

1 | Conductivity | μS/cm | ≤100 |

2 | pH | Dimensionless | 6-7.5 |

3 | Hexavalent Chromium | mg/L | 0.2 |

4 | Chromium | mg/L | 0.2 |

5 | Nickel | mg/L | 0.1 |

6 | Zinc | mg/L | 0.3 |

7 | Copper | mg/L | 0.1 |

8 | Cyanide | mg/L | ND |

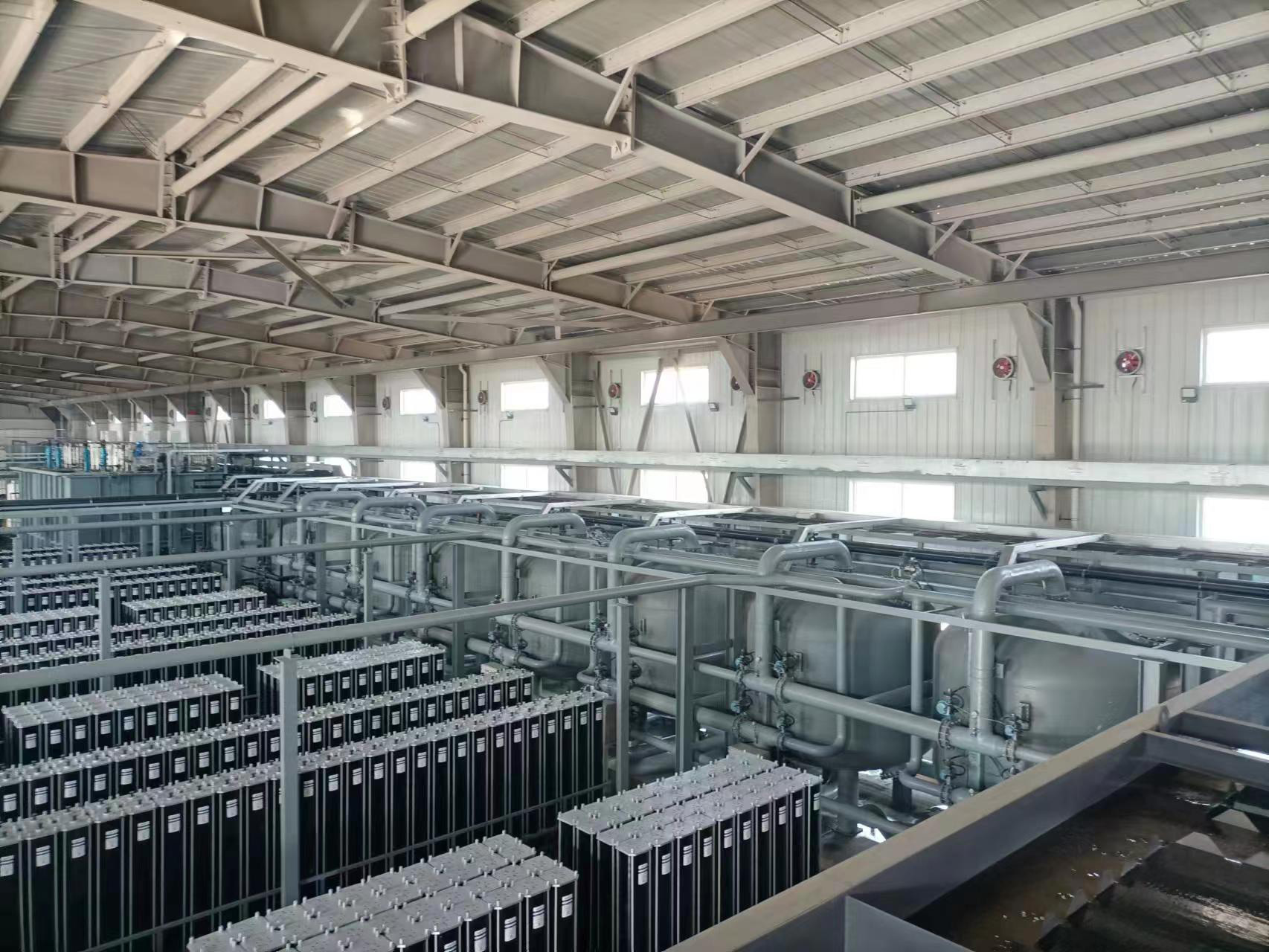

Special Tubular Reverse Osmosis Membrane SUPER DT-RO

Number of Units: 2 sets

Recovery Rate: 65%

Control Method: Fully automatic operation

Membrane Module: Membrane module

Model: SPDT-RO-0916

Single Membrane Area: 9.52 ㎡

Number of Membrane Elements per Set: 80 pieces, total 2 sets

Total Number of Membrane Elements: 160 pieces

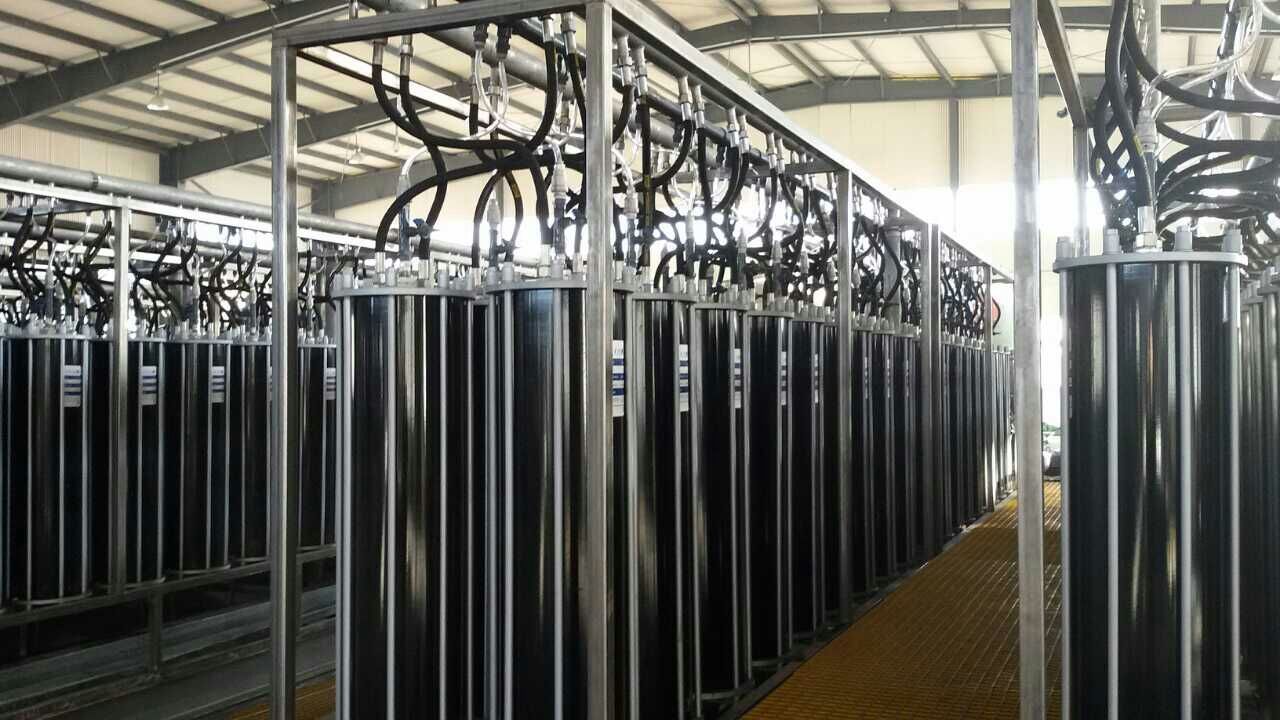

Special High Flux Flat Membrane DMBR

Design Treatment Capacity: 52.1 m³/h (2000 m³/d)

Membrane Module: Membrane module

Model: MFT-DMBR1.5

Structure Type: High flux flat membrane

Membrane Material: PVDF

Number of Membrane Tanks: 16 tanks, 8 tanks/set, total 2 sets (in parallel operation)

——The First Zero Liquid Discharge Project for Pharmaceutical Wastewater in China

This is currently the largest zero liquid discharge project using specialized membranes for secondary water reuse in Asia. The pharmaceutical company is one of the largest antibiotic producers in the country. The project focuses on the zero liquid discharge treatment of highly concentrated and salty pharmaceutical wastewater, mainly including penicillin production wastewater, concentrate from water production systems, circulating water drainage, and biochemical effluent.

The project was completed and put into operation in 2012, utilizing spiral-wound reverse osmosis (RO) membranes + DTRO membrane products to achieve zero liquid discharge through reclaimed water reuse from pharmaceutical wastewater. The treated wastewater is reused in the production process, resulting in no effluent discharge. The completion of this project not only solved the problem of pharmaceutical wastewater treatment for the company but also pioneered zero discharge of pharmaceutical wastewater in the country at that time, becoming a benchmark case for green and sustainable development in the industry.

Inlet and Outlet Water Quality Parameters

Waste Water Type | Design Capacity | Inlet Water Quality Parameters | Outlet Water Quality Parameters |

Penicillin Production Wastewater, Concentrate from Water Systems, Circulating Water Drainage, and Biochemical Effluent | Total designed inlet flow 6,300 m³/day, final concentrate only 500 m³/day, with a recycled water reuse rate above 92% | Conductivity 14,000 μs/cm | Conductivity 500 μs/cm |

Total Salts 8,000 mg/L | Total Salts 300 mg/L | ||

Total Hardness (as CaCO₃) 580 mg/L | Total Hardness 200 mg/L | ||

Alkalinity 333 mg/L | Alkalinity 150 mg/L | ||

COD 260 mg/L | COD 50 mg/L | ||

Chloride Ions 3,200 mg/L | Chloride Ions 100 mg/L |

The project was commissioned in December 2014 and operates normally, handling a total volume of 6,300 t/d. The entire treatment process uses spiral-wound RO + SUPER RO + evaporation, with over 400 SUPER RO membrane elements being used.

Special Spiral-Wound RO Membrane (High Fouling Resistance Spiral-Wound Reverse Osmosis Membrane Element)

Effective Membrane Area: 365 (34)

Feed Water Grid: 34 (0.86)

Recovery Rate: 15%

Test Pressure psi (Mpa): 225 (1.5)

Test Solution Concentration NaCl (ppm): 2,000

Stable Desalination Rate: 99.6%

Special Tubular SUPER RO Membrane

Design Recovery Rate: 75%

Single Membrane Area: 9.5 m²/piece,

Pressure Rating: 90 bar

Number of Membranes: Approximately 400

This project is a key and difficult point in the local textile dyeing wastewater treatment field. It uses the BOT business cooperation model, where Meifute invests in constructing a complete reclaimed water reuse system for textile dyeing wastewater and operates the system.

The reclaimed water produced is reused by the owner in their production. After operation, the project achieves a treatment capacity of 12,000 tons per day, with a reclaimed water output of 7,200 tons per day. The influent electrical conductivity is ≤16,000 μs/cm and COD ≤200 mg/L. The client required that the effluent electrical conductivity be ≤3,000 μs/cm and COD ≤20 mg/L. However, in reality, after processing through Meifute's wastewater treatment system, the COD is not only below 20 mg/L but the electrical conductivity is also below 1,000 μs/cm, far exceeding the effluent standards stipulated in the contract.

Design Inlet Water Quality

Process Unit | COD (mg/L) | Color (mg/L) | SS (mg/L) | Conductivity (μs/cm) | Total Hardness as CaCO₃ (mg/L) | Turbidity (NTU) | pH |

Effluent from Biological System | ≤200 | ≤60 | ≤100 | ≤16,000 | ≤100 | ≤50 | 6.5~8.5 |

Design Outlet Water Quality

Process Unit | pH (dimensionless) | COD (mg/L) | Color (mg/L) | SS (mg/L) | Conductivity (μs/cm) |

Reclaimed Water Quality | 6.5~8.5 | ≤20 | ≤5 | ≤5 | ≤3,000 |

Specialized Tubular RO Membrane (Highly Anti-Pollution Tubular RO Element)

Effective membrane area: 365 (34)

Feed grid size: 34 (0.86)

Recovery rate: 15%

Test pressure psi (Mpa): 225 (1.5)

Test solution concentration NaCl (ppm): 2.000

Stable desalination rate: 99.6%

Specialized Tubular NF Membrane (Low Pressure Nanofiltration Element)

Effective membrane area: 365 (34)

Feed grid size: 34 (0.86)

Recovery rate: 15%

Test pressure psi (Mpa): 100 (6.9)

Test solution concentration NaCl (ppm): 2.000

Stable desalination rate: 98%

— Zero Liquid Discharge and Resource Recovery Project for Chemical Industrial Parks

The Ningxia Pingluo Industrial Park is a specialized industrial zone for new chemical materials and fine chemicals, hosting over a hundred enterprises. It plays a crucial role in supporting the automotive, aerospace, electronics information, green environmental protection, and other industries in the surrounding areas, thereby promoting regional and national industrial development.

Due to the high volume of wastewater generated from chemical production and the scarcity of local water resources, coupled with the significant responsibility of ecological protection in the Yellow River Basin, the local government has implemented the "three red lines" system and the "production based on water availability" policy for water resource management. Through water rights conversion, 14 million cubic meters of water were allocated for the base's production needs; however, there remains a significant shortfall in water supply for the enterprises within the park, constraining the sustainable development of the park.

To solve the water scarcity issue, the park's leadership actively sought solutions for wastewater resource utilization and planned to adopt conventional zero discharge processes to build a reclaimed water plant with a capacity of 10,000 cubic meters per day. However, it was found during expert consultations that the amount of concentrated brine and sludge produced by this method would have to be treated as hazardous waste, making the investment and operational costs too high for the companies to bear. Therefore, there was an urgent need for an economical, reliable, technologically mature, and environmentally friendly zero emission technology. After extensive comparisons, Meifute's "MFT-MORE Industrial Wastewater Zero Emission and Salt Resource Recovery Process" emerged as the best solution.

Inlet and Outlet Water Quality Parameters

The inlet water quality for this project's reclaimed water system is the effluent from the park's wastewater treatment plant that meets the discharge standards. The design inlet water quality is based on the discharge standards of the wastewater treatment plant, including the Surface Water Quality Standards (Class IV), the Integrated Wastewater Discharge Standard (GB 8978-1996), and the Urban Sewage Effluent Quality Standard (GB/T 31962-2015). The specific parameters are listed in the table below:

Sequence No. | Parameter (mg/L) | Reclaimed Water Inlet Quality Standard |

1 | pH | 6-9 |

2 | Color | 30.0 |

3 | Turbidity | - |

4 | Suspended Solids | 10.0 |

5 | BOD5 | 6.0 |

6 | COD | 30.0 |

7 | Ammonia-Nitrogen | 1.5 (3) |

8 | Total Nitrogen | 15.0 |

9 | Total Phosphorus | 0.3 |

10 | Surfactants | 0.5 |

11 | Animal & Plant Oil | 1.0 |

12 | Petroleum | 1.0 |

13 | Fecal Coliforms (CFU/L) | 1000 |

14 | Total Hardness | 250 |

15 | Total Alkalinity | 200 |

16 | Dissolved Solids | 2000 |

17 | Iron | 10 |

18 | Manganese | 5 |

19 | Chloride Ion | 600 |

20 | Sulfate Ion | 600 |

21 | Dissolved Oxygen | - |

22 | Residual Chlorine (mg/L) | - |

23 | Ascaris Eggs (Eggs/L) | 1 |

Designed Outlet Water Standards

The primary reuse targets for the reclaimed water in this project are industrial use, urban miscellaneous use (partially), and environmental use. Therefore, the standards for reclaimed water used in green space irrigation (GB/T25499-2010), urban miscellaneous use (GB/T18920-2002), landscape environment use (GB/T18921-2019), and industrial use (GB/T19923-2005) were analyzed, adopting the most stringent indicators, resulting in the final reclaimed water outlet quality standards. The specific requirements are shown in the table below:

Sequence No. | Parameter (mg/L) | Reclaimed Water Outlet Quality Standard |

1 | pH | 6-9 |

2 | Color | 15.0 |

3 | Turbidity | 5.0 |

4 | Suspended Solids | 10.0 |

5 | BOD5 | 6.0 |

6 | COD | 30.0 |

7 | Total Nitrogen | 10.0 |

8 | Total Phosphorus | 0.3 |

9 | Total Hardness | 250 |

10 | Total Alkalinity | 200 |

11 | Dissolved Solids | 1000 |

12 | Chloride Ion | 250 |

13 | Sulfate Ion | 250 |

Requirements for Crystallized Salts

According to the current national standards and considering the market demand for crystallized salts intended for resource recovery, the quality of recovered sodium chloride and sodium sulfate should meet the following minimum control criteria.

Anhydrous Sodium Sulfat

The quality of anhydrous sodium sulfate complies with the requirements of T/CCT001-2019.

Sodium Chloride

The quality of sodium chloride complies with the requirements of T/CCT002-2019.

The MFT-MORE process employs "pre-treatment + multi-stage specialized membrane concentration + MVR evaporation." The membrane concentration system consists of SUPER DT-RO specialized high-pressure reverse osmosis membranes and SUPER DT-NF specialized high-pressure nanofiltration membranes.

SUPER DT-RO Specialized High-Pressure Reverse Osmosis Membranes

Ⅰ- Disc-tube RO System

Design recovery rate: 90%

Single membrane area: 15㎡/unit

pressure level: 30bar

Number of membranes: 240 units/set,total 4 sets,totaling 960 units

Ⅱ- Disc-tube RO System

Design recovery rate: 75%

Single membrane area: 15㎡/unit,

pressure level: 90bar

Number of membranes: 130 units/set, total 2 sets, totaling 260 units

Ⅳ- Disc-tube RO System

Design recovery rate: 70%

Single membrane area: 9.5㎡/unit,

pressure level: 160bar

Number of membranes: 40 units/set, total 2 sets, totaling 80 units

SUPER DT-NF Specialized High-Pressure Nanofiltration

Ⅲ- Disc-tube NF System

Design recovery rate: 71%

Single membrane area: 9.5㎡/unit,

pressure level: 160bar

Number of membranes: 34 units/set, total 2 sets, totaling 68 units

After being highly concentrated by the high-pressure reverse osmosis membranes, the concentrated water enters the specialized high-pressure nanofiltration membrane system for salt separation. The minimal amount of concentrated brine after separation is processed through MVR evaporation to produce high-quality industrial-grade sodium chloride (T/CCT002-2019) and sodium sulfate (T/CCT001-2019). The overall recovery rate of the specialized membrane system reaches up to 98.6%, with the effluent exceeding the standards for reclaimed water use, suitable for industrial water supply in the park. Additionally, it can be used for landscape greening and urban miscellaneous reuse, reducing the daily amount of residual salts by nearly 95% compared to traditional zero-discharge processes. This results in annual savings of millions in residual salt disposal costs and generates millions more in economic value from the high-quality industrial salts.

— Implementing the Strictest Discharge Standards in the Electroplating Industry

The zero-discharge environmental protection project for electroplating wastewater at the Yudong Surface Treatment Center is the first zero-discharge project for electroplating wastewater in Southwest China, implementing the strictest national discharge standards for pollutants in electroplating industry wastewater.

The scale of wastewater treatment is 3,000 tons per day, all of which is recycled. Based on over two decades of experience in the field of industrial wastewater treatment and the formation of “comprehensive service capability along the entire process chain,” Meifeng Environment, targeting the complex composition of wastewater in the park, large fluctuations in water quality and quantity, high concentrations of pollutants such as heavy metals, and poor biodegradability, adopted the principle of "categorized collection and differentiated treatment."

By using the domestically top-notch and internationally advanced "MFT-MORE Zero-Discharge and Resource Recovery Process Package," it can stably and efficiently achieve zero-discharge of electroplating wastewater in the park and the recovery and resource utilization of valuable substances, significantly reducing the environmental risks of the park.

Design Inlet Water Quality Parameters

Type of Wastewater | COD | Cr | Zn | Cu | Ni | Conductivity |

Chromium-Containing | ≤80 mg/L | / | ≤16 mg/L | ≤32 mg/L | / | ≤2569 μS/cm |

Mixed Discharge | ≤280 mg/L | ≤1.4 mg/L | ≤50 mg/L | ≤200 mg/L | ≤50 mg/L | ≤12436 μS/cm |

Nickel-Containing | ≤122 mg/L | / | ≤6 mg/L | ≤7 mg/L | ≤28 mg/L | ≤7357 μS/cm |

Cyanide-Containing | ≤300 mg/L | / | / | ≤320 mg/L | / | ≤9906 μS/cm |

Complex/Comprehensive | ≤128 mg/L | / | ≤27 mg/L | ≤185 mg/L | / | ≤3735 μS/cm |

Mixed Discharge | ≤47 mg/L | / | ≤21 mg/L | ≤13 mg/L | / | ≤5116 μS/cm |

Designed Effluent Quality Parameters:

Membrane Treated Water: Chromium-containing wastewater, nickel-containing wastewater, cyanide-containing wastewater, mixed wastewater, and composite/complex wastewater treated by the membrane system comply with the "Chongqing Plating Industry Wastewater Pollutants Voluntary Emission Standard" (T/CQSES02-2017).

No. | Pollutant Category | Voluntary Standard | Table 3 Standard | Agreement Requirements | Planning, Construction, Design, and Operation Standards |

Standard Value | Monitoring Position | Implementation Standard |

|

|

|

1 | Total Chromium | 0.2 | 0.5 | / | Workshop or Production Facility Wastewater Discharge Point |

2 | Hexavalent Chromium | 0.05 | 0.1 | / | 0.05 |

3 | Total Nickel | 0.1 | 0.1 | / | 0.1 |

4 | Total Cadmium* | 0.001 | 0.01 | / | 0.001 |

5 | Total Silver | 0.001 | 0.1 | / | 0.001 |

6 | Total Lead* | 0.01 | 0.1 | / | 0.01 |

7 | Total Mercury* | 0.001 | 0.005 | / | 0.001 |

8 | Total Tin | / | / | / | Shanghai Local Standard "Wastewater Integrated Emission Standard" (DB31/199 -2018) |

Special Membrane Applications

A multi-stage multistage membrane concentration system centered around special membranes was used, employing nearly 1500 special membranes in total.

Approximately 100 special ultrafiltration membranes, using tubular ultrafiltration, with a designed water production rate of ≥95%, primarily for concentrating and removing COD and BOD, as well as further removal of suspended solids.

300 special spiral wound nanofiltration membranes with a desalination rate of ≥99.0%, for concentrating and separating mixed salts and removing heavy metals.

Nearly 1100 special spiral wound reverse osmosis membranes, with a system desalination rate of primary stage ≥98.5%, secondary stage ≥99%, concentrated liquid RO membrane removal rate ≥99.5%. The main purpose is to concentrate and remove heavy metal pollution factors, with concentrated liquid entering the evaporation system for thorough concentration and drying, producing reclaimed water for reuse.

The hazardous waste liquid treated in this project mainly includes acidic and alkaline waste liquids, copper-containing waste liquids, nickel-containing wastewater, chromium-containing waste liquids, cyanide-containing waste liquids, and leachate from landfills.

After preliminary physicochemical treatment, the original wastewater enters a conditioning tank to adjust the water quality, then sequentially passes through anaerobic, anoxic, and aerobic tanks to degrade organic pollutants in the wastewater.

Subsequently, the wastewater goes through an MBR tank to remove most of the sludge, followed by ultrafiltration and spiral-wound reverse osmosis. The permeate water from the reverse osmosis process flows into a clear water tank. Due to severe fouling during the operation of the spiral-wound reverse osmosis system, it was difficult to operate normally and did not meet the surface water standards (GB3838-2002).

Therefore, it was necessary to renovate the reverse osmosis system. Meifute conducted on-site pilot tests using specialized reverse osmosis membranes and, after long-term validation, ultimately chose a process centered around SUPER RO specialized membranes for the renovation.

Wastewater Type | Design Scale | Raw Water Inlet Quality Indicators | Outlet Water Quality Indicators |

Hazardous Waste Liquid Post-Treatment Wastewater | System design inflow 200m³/d;<br>Designed overall recovery rate ≥75% | COD 400mg/L<br>Ammmonia Nitrogen 300mg/L<br>Conductivity 30000μs/cm | COD≤20mg/L<br>BOD5≤4mg/L<br>NH3-N≤1.0mg/L |

Specialized Tubular RO Membrane (Highly Anti-Pollution Tubular RO Element)

Effective membrane area: 365 (34)

Feed grid size: 34 (0.86)

Recovery rate: 15%

Test pressure psi (Mpa): 225 (1.5)

Test solution concentration NaCl (ppm): 2.000

Stable desalination rate: 99.6%

Specialized Disc-Tube RO Membrane System

Designed recovery rate: 70%

Single membrane area: 9.5㎡/element, pressure rating: 160bar

Specialized Disc-Tube NF Membrane System

Designed recovery rate: 71%

Single membrane area: 9.5㎡/element, pressure rating: 160bar

——CNPC's Highest-Level Feasibility Study Project

Sinopec Southwest Branch is currently developing the Heba Gas Field, which entered trial production in 2007 and has since had stable natural gas production and formation water generation. Alongside the development of this block, a large amount of gas production and transportation wastewater is generated, containing pollutants such as COD and hydrocarbons.

Direct discharge would inevitably cause serious environmental pollution. CNPC Oil Services and Meifute jointly carried out a 15-day pilot test of the Super RO membrane system for treating gas field wastewater in December 2013.

Based on the test results and existing conditions at the project site, they designed the most reasonable and effective specialized membrane wastewater treatment process. Throughout the implementation and acceptance phase of the project, it received high praise from customers.

Wastewater Type | Design Scale | Raw Water Inlet Quality Indicators | Outlet Water Quality Indicators |

Gas Field Formation Produced Water | System design inflow 250m³/d;<br>Designed overall recovery rate ≥70% | COD 1000 mg/L<br>Cl- 20000 mg/L<br>Total Oil ≤10 mg/L<br>Conductivity 30000μs/cm | COD≤50mg/L<br>Cl-200 mg/L<br>Total Oil ≤5 mg/L<br>Conductivity ≤700μs/cm |

Specialized Tubular RO Membrane (Highly Anti-Pollution Tubular RO Element)

Effective membrane area: 365 (34)

Feed grid size: 34 (0.86)

Recovery rate: 15%

Test pressure psi (Mpa): 225 (1.5)

Test solution concentration NaCl (ppm): 2.000

Stable desalination rate: 99.6%

Specialized Disc-Tube RO Membrane System

Designed recovery rate: 70%

Single membrane area: 9.5㎡/element

pressure rating: 160bar

Specialized Disc-Tube NF Membrane System

Designed recovery rate: 71%

Single membrane area: 9.5㎡/element,

pressure rating: 160bar

— Awarded "Model Park for China's Electroplating Industry"

This electroplating industrial park is one of the designated environmental industrial parks approved by a provincial government, covering an area of approximately 472,800 square meters. It plans to construct standard factory buildings and supporting life facilities covering around 450,000 square meters, serving as a model park for the electroplating industry in terms of "energy saving, emission reduction, clean production, and environmental management" at both the national and provincial levels. The park currently handles a daily wastewater volume of 12,000 tons, realizing the initial concept of "centralized pollution control, cyclic production, and environmental protection."

After taking over the project, Mefute designed an engineering solution combining super reverse osmosis with evaporation, tailored to the complex composition of electroplating wastewater and the high metal content. From the current operational status, Mefute not only meets the requirements for treated water quality set by the electroplating base but also achieves the high standard of zero-discharge through reclaimed water reuse.

Type of Wastewater | Design Scale | Inlet Water Quality Indicators | Outlet Water Quality Indicators |

Electroplating Wastewater | System design inflow 240m³/d; Total designed recovery rate ≥75% | pH 6-9 <br> COD ≤500 mg/L <br> Hardness ≤ 300 mg/L <br> Conductivity ≤30000 μs/cm <br> Salt Content ≤1.5% <br> SDI≤20 | pH 6-9 <br> COD≤60 mg/L <br> Conductivity ≤2000 μs/cm |

Special Spiral Wound RO Membrane (Highly Pollution Resistant Spiral Wound Reverse Osmosis Element)

Effective membrane area: 365 (34)

Feed spacer: 34 (0.86)

Recovery rate: 15%

Test pressure psi (Mpa): 225 (1.5)

Test solution concentration NaCl (ppm): 2.000

Stable desalination rate: 99.6%

Special Tubular SUPER DT-RO

Design recovery rate: 70%

Single membrane area: 9.5㎡/element,

pressure class: 160 bar