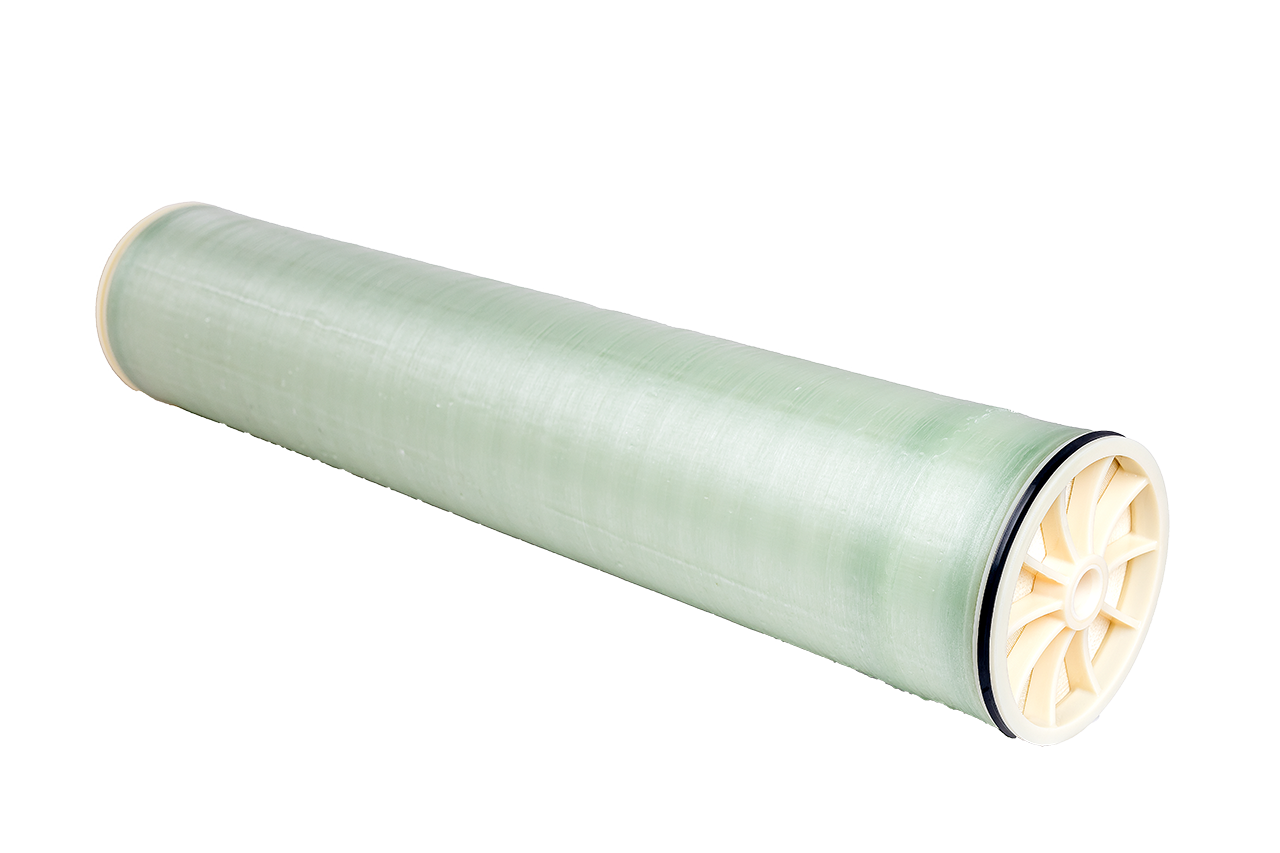

SPNF Specialized Spiral-Wound Nanofiltration Membrane Elements

SPNF 380-41-270 spiral-wound nanofiltration membrane elements efficiently separate monovalent and divalent salts from industrial wastewater, enabling the recycling and reuse of salts, as well as wastewater reuse.

SPNF 365-83-270 anti-pollution spiral-wound nanofiltration membrane elements are used for separating high TDS, high-salt wastewater, monovalent and divalent salts in industrial wastewater, achieving further purification and concentration separation. When treating high TDS, high-salt wastewater containing monovalent ions (such as chloride ions) and divalent ions (such as sulfate ions), the pressure required may exceed 400 psi. The system operating pressure of spiral-wound nanofiltration membranes SPNF 365-83-270 is between 400 - 1200 psi, which further improves separation efficiency compared to standard pressure spiral-wound nanofiltration membranes SPNF 365-41-270.

Product advantages:

•Spiral-wound nanofiltration membranes have high selectivity, effectively intercepting divalent ions and COD, with high permeability for monovalent ions, helping to separate high-purity salt solutions while reducing concentrate volumes.

•They have a higher effective membrane area, reducing system investment under the same usage conditions.

•The membrane sheets have good antioxidant and acid-base resistance properties, ensuring long-term stable production capacity.

Membrane Element Model | Cut-off Molecular Weight Da | Effective Membrane Area m² (ft²) | Feed Grid mil (mm) | Product Water Yield GDP (m³/d) | Stable Desalination Rate % | Minimum Desalination Rate % |

SPNF1HP365/34 | 90 | 365 (34) | 34 (0.86) | 8500 (32) | 98 | 96 |

SPNF3HP365/34 | 270 | 365 (34) | 34 (0.86) | 10500 (40) | 98 | 95 |

Testing conditions:

1)Test pressure: 100 psi (0.69 MPa)

2)Test solution temperature: 25°C

3)Test solution concentration (MgSO₄): 2000 ppm

4)Test solution pH value: 7.5

5)Recovery rate of single membrane element: 15%

产品尺寸:

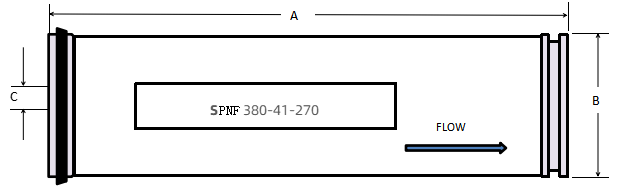

All dimensions in the diagram are given in millimeters (inches).

A=1016.00mm(40”); B=201.90mm(7.95”); C=28.60mm(1.125”)

Operating limits:

1)Maximum operating pressure: 1200 psi (8.3 MPa)

2)Maximum feed water flow rate: 75 gpm (17 m³/h)

3)Maximum feed water temperature: 45°C

4)Maximum SDI15 of feed water: 5,

5)Free chlorine concentration in feed water < 0.1 ppm

6)Feed water pH range during continuous operation: 3~10

7)Feed water pH range during chemical cleaning: 2~12

8)Maximum pressure drop of a single membrane element: 15 psi (0.1 MPa)

SPNF 380-41-270

High anti-pollution salt separation NF membrane element

Used for efficient separation of monovalent and divalent salts in industrial wastewater, achieving recycling and reuse of salts.

SPNF 365-83-270

High anti-pollution salt separation NF membrane element

Used for separation of monovalent and divalent salts in high TDS industrial wastewater, achieving further purification and concentration separation.

产品选型指南:

SPRO 380-41-LD34 High Fouling Resistance | |||||||||

SPRO 365-83-34High Fouling Resistance | |||||||||

SPRO 330-120-34High Fouling Resistance | |||||||||

BW Series | |||||||||

SW Series | |||||||||

500 | 1000 | 2000 | 5000 | 10000 | 30000 | 50000 | 80000 | 120000 | |

SUPER DT-NF Specialized Disc Tube Nanofiltration Membrane DTNF

High Concentration High Anti-Pollution

Certified by: TÜV, CE, ISO9001, ISO14001, OHSAS 18001

High Concentration

★Flow Distributor: Patented Design

The coin-slot design of the flow distributor ensures that the feed flows over the membrane surface in a radar scanning manner, creating a vortex-like spiral throughout the membrane column. This reduces the transmembrane pressure difference to only 2-3 kg, resulting in a 50% reduction in pressure loss compared to traditional DT systems, making it more energy-efficient.

★Membrane Sheets: Patented Material Modification Formula and Special Membrane Manufacturing Process with Larger Membrane Area

1. Optimized molecular structure of the support layer of the membrane sheets, enhancing compressive strength and preventing compaction under high pressure.

2. Improved stability of the bridging polyamide multi-dimensional structure in the functional separation layer, leading to more stable membrane performance and greater resistance to chemical shocks.

3. Membrane area increased by 20% compared to traditional DT, offering better cost-effectiveness.

★Membrane Module: Special Structural Design

Designed with a high-pressure-resistant structure, the membrane module does not deform under high pressure, allowing safe operation at up to 160 bar, which is 3-5 times higher than traditional spiral-wound RO systems. It offers nearly double the concentration ratio compared to traditional DT, enabling ultra-concentration and reduced evaporation.

High Anti-Pollution

1. The membrane sheets have a thicker separation layer (approximately twice that of traditional DT), improving cleanability and extending the lifespan of the membrane.

2. The membrane surface is electrically neutral, reducing the adhesion of pollutants and microorganisms, thus being more resistant to fouling.

3. Open channel design with a flow channel width of 2.5 mm (an increase of over 66% compared to traditional DT), wider fluid channels prevent clogging, suitable for concentrating high-concentration, high-salinity, and high-organic content materials, requiring less pretreatment and providing better anti-fouling performance.

4. Linear protrusion design of the flow distributor creates turbulence at the protrusions, with a Reynolds number Re > 2500, resulting in better self-cleaning effects and reduced cleaning frequency.

Membrane Element Model | Area/m² | Pressure/bar | Flow Channel/mm |

SPDT-NF(100)-0990 | 9.5 | 90 | 2.5 |

SPDT-NF(100)-0916 | 9.5 | 160 | 2.5 |

SPDT-NF(300)-0990 | 9.5 | 90 | 2.5 |

SPDT-NF(300)-0916 | 9.5 | 160 | 2.5 |

★Resource recovery from industrial wastewater desalination

★Recovery of precious metals/removal of heavy metals from industrial wastewater