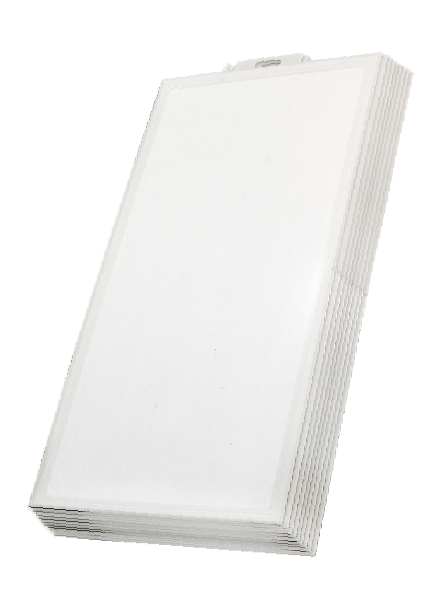

High-Flux Flat-Sheet Membrane DMBR

A revolutionary product disrupting traditional MBR

High flux (30~35LMH)

After five years of experimental research and engineering applications, the membrane technology R&D team has successfully developed a special ultrafiltration membrane —— large-flux flat sheet membrane DMBR. Using PVDF + EVOH special composite material modification technology to improve the membrane formulation and process, optimizing the membrane pore structure, reducing the transmembrane resistance, making the membrane sheet have better hydrophilic properties, the membrane flux is increased by 30% compared to traditional formulations, offering better cost-effectiveness.

Under the same influent conditions:

Lower investment and price costs

The DMBR membrane flux is about 0.5~0.8 times that of traditional MBR flat sheet membranes, approximately 1-~1.5 times that of MBR hollow fiber membranes. In the same circumstances, less membrane area is required, the investment is comparable to MBR hollow fiber membranes, but 50% lower than traditional MBR flat sheet membranes, resulting in even lower investment costs.

Lower operation and maintenance costs

Under the same operating conditions, DMBR membranes require less usage, smaller aeration volume, reduced blower energy consumption, equivalent to MBR hollow fiber membranes, but 50% lower than traditional MBR flat sheet membranes. DMBR membranes have a lower cleaning frequency, consume less chemicals, saving around 50% on chemical costs compared to traditional flat sheet MBR membranes.

Lower membrane depreciation costs

The service life of DMBR membranes is more than 5 years, whereas MBR hollow fiber membranes last only 1~3 years, resulting in lower membrane depreciation costs.

Comparison of DMBR membranes with traditional MBR membranes (using 10000t/d municipal wastewater as an example):

Item | DMBR | Hollow Fiber MBR Membrane | Traditional Flat Sheet MBR Membrane |

Mechanical Strength | Good, no fiber breakage | 14900㎡ | Good, no fiber breakage |

Anti-Pollution Performance | Strong, superior hydraulic conditions of flat sheet membranes | Rapid pollution | Strong, superior hydraulic conditions of flat sheet membranes |

| Service Life | Over 5 years, individual membranes can be repaired | 2-5 years, non-repairable | Over 5 years, individual membranes can be repaired |

Cost per Unit Area of Membrane Element | Approximately twice that of MBR hollow fiber membranes | Average | Approximately twice that of MBR hollow fiber membranes |

Designed Membrane Flux | 30~35LMH | 13~17LMH | 18~25LMH |

Number of Membranes Used | 14900㎡ | 28940㎡ | 20900㎡ |

Membrane Element Model | Membrane Area | Specifications (LxWxH mm) |

M08 | 0.80 | 1040×488×7.5 |

M15 | 1.50 | 1776×488×7.5 |

Pore size: <0.1um

Application: Solid-liquid separation in membrane bioreactors

Filtration method: Suction filtration

Industrial wastewater deep treatment | Replacing traditional submerged ultrafiltration | Municipal wastewater upgrading | Village and town sewage treatment | Reclaimed water treatment

Specialized Spiral-Wound Ultrafiltration Membrane SPUF

High flux, no fiber breakage in spiral wound structure; only replace the membrane core, not the housing.

★Highly anti-pollution specially modified proprietary membrane sheet

Molecular design and precise interfacial polymerization technology —— enhancing the bridging polyamide multi-dimensional structure of the functional separation layer, improving chemical resistance;

Special modified proprietary formula + surface modification treatment technology —— the membrane material approaches electrical neutrality, the membrane surface is smoother, less prone to adsorb pollutants and microorganisms, better anti-pollution performance.

★Anti-pollution membrane element structural design

1.Optimized flow channel design, ensuring uniform distribution of feed water, reducing "dead water" zones within the channels, more resistant to fouling blockages, cleaning frequency reduced by over 40%.

2.Shorter membrane leaves, thus the distance from the membrane bag end to the product water pipe is shorter, the product water permeate flux is more evenly distributed along the membrane sheet, significantly reducing the rate of fouling.

3.Low-pressure drop flow channel design, low initial membrane pressure difference, the time it takes for the cleaning pressure difference to reach the boundary value can be extended by 80%, reducing cleaning frequency.

Model | Ultrafiltration Cut-off Molecular Weight or Pore Size | Effective Membrane Area m² | Flow Channel Type and Width | Appearance |

SPUF-1n-8040-N80-G | 10nm | 18 | Diamond-shaped 80mil | Fiberglass Reinforced Plastic |

SPUF-5n-8040-N30-G | 50nm | 34 | Diamond-shaped 32mil | Fiberglass Reinforced Plastic |

SPUF-10n-8040-N45-G | 100nm | 27 | Diamond-shaped 45mil | Fiberglass Reinforced Plastic |

Mainly used for water supply treatment scenarios, turbidity removal scenarios.