SPRO Specialized Spiral-Wound Reverse Osmosis Membrane Elements

Strong hydrophilicity of the membrane sheet, large flux, low energy consumption.

|

|

MFT-MS |

Domestic Brand |

International Brand |

|

Contact angle | 69.0° |

69.1° |

80.1° |

Smooth surface of the membrane sheet, nearly electrically neutral, less prone to adsorb contaminants.

Roughness index reduced by more than 50% compared to domestic brands, about 20% lower than international brands.

Special modification of the membrane material, antioxidant, resistant to chemical cleaning, long service life.

In cyclic anti-pollution simulation experiments:

Flux decline reduced by approximately 86% compared to domestic brands, around 85% lower than international brands.

Desalination change rate reduced by approximately 32% compared to domestic brands, around 46% lower than international brands.

Special wide flow channel design, more resistant to fouling blockage, reduces pressure vessel pressure drop, good cleaning recovery effect.

Wider flow channel (34mil) + low-pressure differential feed grid 34LD + shorter and more numerous membrane leaves (26~27)

Special modified membrane sheets, specially designed pressure-bearing product water guide cloth, more resistant to high pressure, maximum operating pressure up to 120bar.

Precision interfacial reaction control process and excellent hydrophilic modification coating technology, under the same usage conditions, the membrane flux is superior.

Membrane flux is approximately 1.38 times that of domestic brands, more than 1.2 times that of international brands.

Membrane Element Model | Effective Membrane Area ft2(m2) | Feed Grid mil(mm) | Product Water Yield GDP(m3/d) | Stable Desalination Rate % | Minimum Desalination Rate % |

SPRO 380-41-LD34 | 380(35.3) | 34(0.86) | 11500(43.5) | 99.6 | 99.2 |

SPRO 365-83-34 | 365(34) | 34(0.86) | 8200(31) | 99.5 | 99.2 |

SPRO 330-120-34 | 330(30.7) | 34(0.86) | 7400(28) | 99.5 | 99.2 |

Test pressure: 225 psi (1.55 Mpa)

Test solution temperature: 25°C, test solution concentration (NaCl) 2000 ppm

Test solution pH value: 7.5

Recovery rate of single membrane element: 15%

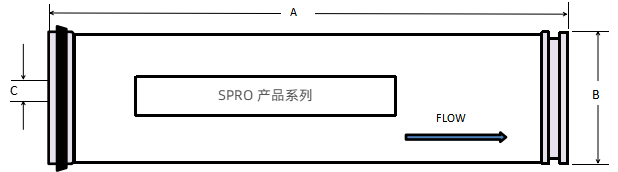

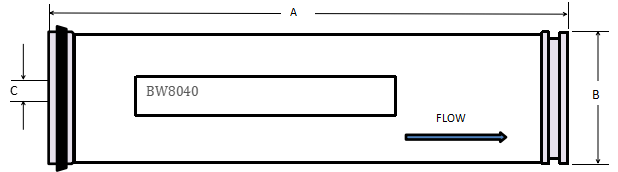

Membrane Element Dimensions:

all units shown are in millimeters (inches)

A=1016.00mm(40”); B=201.90mm(7.95”); C=28.60mm(1.125”)

Operating limits:

Operating Conditions | SPRO 380-41-LD34 | SPRO 365-83-34 | SPRO 330-120-34 |

Maximum operating pressure | 600psi(4.14Mpa) | 1200psi(8.3Mpa) | 1740psi(12Mpa) |

Maximum feed water flow rate | 75gpm(17 m³/h) | 75gpm(17 m³/h) | 75gpm(17 m³/h) |

Maximum feed water temperature | 45℃ | 45℃(pressure ≤ 8.3MPa) | 45℃(pressure ≤ 8.3MPa) |

| 30℃(pressure > 8.3MPa) | 30℃(pressure > 8.3MPa) | 30℃(pressure > 8.3MPa) |

Maximum SDI15 of feed water | 5 | 5 | 5 |

Free chlorine concentration in feed water | <0.1ppm | <0.1ppm | <0.1ppm |

pH range | Continuous operation feed water pH range 3~10, chemical cleaning feed water pH range 2~12 | Continuous operation feed water pH range 3~10, chemical cleaning feed water pH range 2~12 | Continuous operation feed water pH range 3~10, chemical cleaning feed water pH range 2~12 |

Maximum pressure drop of a single membrane element | 15psi(0.1Mpa) | 15psi(0.1Mpa) | 15psi(0.1Mpa) |

SPRO 380-41-LD34

High anti-pollution reverse osmosis membrane element

Used for near-zero discharge and resource recovery of wastewater, suitable for wastewater with total dissolved solids (TDS) below 10,000 mg/L, especially suitable for treating industrial wastewater containing minor organic pollutants, municipal wastewater, and slightly polluted water sources.

SPRO 365-83-34

High anti-pollution reverse osmosis membrane element

Can be used for desalination of highly concentrated brackish water, various industrial water treatments such as boiler feedwater for power plants, and also for wastewater reuse, near-zero discharge high concentration, and concentration recovery of high-value-added substances like food and pharmaceuticals, capable of concentrating TDS in concentrate to 80,000 ppm, improving system recovery rate, and reducing concentrate volume.

SPRO 330-120-34

High anti-pollution reverse osmosis membrane element

Developed specifically to further reduce concentrate volume, this high-pressure spiral-wound membrane product is suitable for concentrating wastewater with salinity levels of 70,000 ppm, capable of concentrating TDS in the concentrate to 105,000 ppm, equally applicable for industrial wastewater reuse, near-zero discharge high concentration, and concentration recovery of high-value-added substances like food and pharmaceuticals.

Selection Guide:

SPRO 380-41-LD34 High Fouling Resistance | |||||||||

SPRO 365-83-34High Fouling Resistance | |||||||||

SPRO 330-120-34High Fouling Resistance | |||||||||

BW Series | |||||||||

SW Series | |||||||||

500 | 1000 | 2000 | 5000 | 10000 | 30000 | 50000 | 80000 | 120000 | |

SUPER DT-RO Specialized Disc Tube Reverse Osmosis Membrane DTRO Membrane

High Concentration High Anti-Pollution

Certified by: TÜV, CE, ISO9001, ISO14001, OHSAS 18001

High Concentration

★Flow Distributor: Patented Design

The coin-slot design of the flow distributor ensures that the feed flows over the membrane surface in a radar scanning manner, creating a vortex-like spiral throughout the membrane column. This reduces the transmembrane pressure difference to only 2-3 kg, resulting in a 50% reduction in pressure loss compared to traditional DT systems, making it more energy-efficient.

★Membrane Sheets: Patented Material Modification Formula and Special Membrane Manufacturing Process with Larger Membrane Area

1. Optimized molecular structure of the support layer of the membrane sheets, enhancing compressive strength and preventing compaction under high pressure.

2. Improved stability of the bridging polyamide multi-dimensional structure in the functional separation layer, leading to more stable membrane performance and greater resistance to chemical shocks.

3. Membrane area increased by 20% compared to traditional DT, offering better cost-effectiveness.

★Membrane Module: Special Structural Design

Designed with a high-pressure-resistant structure, the membrane module does not deform under high pressure, allowing safe operation at up to 160 bar, which is 3-5 times higher than traditional spiral-wound RO systems. It offers nearly double the concentration ratio compared to traditional DT, enabling ultra-concentration and reduced evaporation.

High Anti-Pollution

1. The membrane sheets have a thicker separation layer (approximately twice that of traditional DT), improving cleanability and extending the lifespan of the membrane.

2. The membrane surface is electrically neutral, reducing the adhesion of pollutants and microorganisms, thus being more resistant to fouling.

3. Open channel design with a flow channel width of 2.5 mm (an increase of over 66% compared to traditional DT), wider fluid channels prevent clogging, suitable for concentrating high-concentration, high-salinity, and high-organic content materials, requiring less pretreatment and providing better anti-fouling performance.

4. Linear protrusion design of the flow distributor creates turbulence at the protrusions, with a Reynolds number Re > 2500, resulting in better self-cleaning effects and reduced cleaning frequency.

SPDT-RO Series Model | Pressure Rating(bar) | Single Membrane Area(㎡) | Number of Membrane Bags(Pieces) | Flow Channel(mm) |

SPDT-RO-0990 | 90 | 9.5 | 119 | 2.5 |

SPDT-RO-0916 | 160 | 9.5 | 119 | 2.5 |

Industries: Electroplating, Pharmaceutical, Chemical, Oil and Gas Fields, Hazardous Waste Liquids, Dyeing and Printing, Coal Chemicals, Mines, Thermal Power Plants, etc., for high difficulty wastewater

Application Areas:

★Zero Discharge and Resource Recovery of Industrial Wastewater

★Quantitative Treatment of Leachate from Landfills

SW Series (Seawater Desalination Membranes)

·High desalination rate combined with high boron rejection

·Increased thickness and cross-linking of the skin layer ensure longer membrane lifespan and chemical resistance

· Short membrane leaf design increases the utilization of effective membrane area and reduces the fouling rate of the membrane element

Can replace similar imported products such as Hydranautics and Dow reverse osmosis membranes.

Membrane Element Model | Effective Membrane Area ft2(㎡) | Feed Grid mil(mm) | Average Product Water Yield GPD(m³/d) | Stable Desalination Rate % | Minimum Desalination Rate % |

SW 8040-400/28 | 400(37) | 28 | 8000(30) | 99.7 | 99.5 |

SW 4040-85/28 | 85(7.9) | 28 | 1700(6.4) | 99.6 | 99.4 |

Test pressure: 800 psi (5.52 Mpa)

Test solution temperature: 25°C

Test solution concentration (NaCl): 32000 ppm

Test solution pH value: 7.5

Recovery rate of a single membrane element: 8%

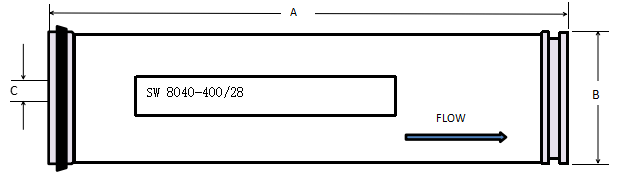

Membrane Element Dimensions:

All dimensions shown are in millimeters (inches)

A=1016.00mm(40”); B=201.90mm(7.95”); C=28.60mm(1.125”)

Operating Conditions | SW 8040-400/28 | SW 4040-85/28 |

Maximum operating pressure | 1200 psi (8.3 MPa) | 1200 psi (8.3 MPa) |

Maximum feed water flow rate | 75 gpm (17 m³/h) | 16 gpm (3.6 m³/h) |

Maximum feed water temperature | 45℃ | 45℃ |

Maximum SDI15 of feed water | 5 | 5 |

Free chlorine concentration in feed water | <0.1 ppm | <0.1 ppm |

pH range | Continuous operation feed water pH range 3~10, chemical cleaning feed water pH range 2~12 | Continuous operation feed water pH range 3~10, chemical cleaning feed water pH range 2~12 |

Maximum pressure drop of a single membrane element | 15 psi (0.1 MPa) | 15 psi (0.1 MPa) |

The SW series (desalination series) is developed specifically for seawater desalination, ensuring a high desalination rate while maintaining a standard product water yield and providing long-term stable desalination performance.

Selection Guide:

|

|

|

|

|

|

|

|

|

|

|

|

SPRO 380-41-LD34 High Fouling Resistance |

|||||||||

|

|

|

|

|

|

|

||||

|

SPRO 365-83-34High Fouling Resistance |

|||||||||

|

|

|

|

|||||||

|

SPRO 330-120-34High Fouling Resistance |

|||||||||

|

|

|

||||||||

|

BW Series |

|||||||||

|

|

|

|

|

|

|||||

|

SW Series |

|||||||||

|

|

|

|

|||||||

|

500 |

1000 |

2000 |

5000 |

10000 |

30000 |

50000 |

80000 |

120000 |

|

BW Series (Brackish Water Membranes)

·Low operational energy consumption, high water production, maintains high desalination rate along with high water yield

·Membrane sheets use an oxidation-free treatment process, ensuring stability and longevity of the membrane

·Can adapt to water quality conditions and temperature environments in most regions

Can replace similar imported products such as Hydranautics and Dow reverse osmosis membranes.

Membrane Element Category | Membrane Element Model | Effective Membrane Area ft2(㎡) | Maximum Pressure bar(psi) | Feed Grid mil(mm) | Average Product Water Yield GPD(m³/d) | Stable Desalination Rate % | Minimum Desalination Rate % |

BW series (brackish water) | BW 8040-365/34 | 365(34) | 41(600) | 34 | 10500(40) | 99.6 | 99.4 |

BW series (brackish water) | BW 8040-400/28 | 400(37) | 41(600) | 28 | 11500(43.5) | 99.6 | 99.4 |

BW series (brackish water) | BW 4040-85/28 | 85(7.9) | 41(600) | 28 | 2450(9.3) | 99.5 | 99.3 |

Testing Conditions:

Test pressure: 225 psi (1.55 Mpa)

Test solution temperature: 25°C

Test solution concentration (NaCl): 2000 ppm

Test solution pH value: 7.5

Recovery rate of a single membrane element: 15%

Membrane Element Dimensions:

All dimensions shown are in millimeters (inches)

A=1016.00mm(40”); B=201.90mm(7.95”); C=28.60mm(1.125”)

Operating Conditions | BW 8040-365/34 | BW 8040-400/28 | BW 4040-85/28 |

Maximum operating pressure | 600 psi (4.14 MPa) | 600 psi (4.14 MPa) | 600 psi (4.14 MPa) |

Maximum feed water flow rate | 75 gpm (17 m³/h) | 75 gpm (17 m³/h) | 16 gpm (3.6 m³/h) |

Maximum feed water temperature | 45℃ | 45℃ | 45℃ |

Maximum SDI15 of feed water | 5 | 5 | 5 |

Free chlorine concentration in feed water | <0.1 ppm | <0.1 ppm | <0.1 ppm |

pH range | Continuous operation feed water pH range 3~10, chemical cleaning feed water pH range 2~12 | Continuous operation feed water pH range 3~10, chemical cleaning feed water pH range 2~12 | Continuous operation feed water pH range 3~10, chemical cleaning feed water pH range 2~12 |

Maximum pressure drop of a single membrane element | 15 psi (0.1 MPa) | 15 psi (0.1 MPa) | 15 psi (0.1 MPa) |

The BW series (brackish water) reverse osmosis membrane elements are mainly used for desalination of brackish water, suitable for surface water and low-salinity groundwater, can be used for purifying drinking water and preparing pure water in fields such as electronics and power generation. This reduces investment costs for related pumps, piping, containers, and other equipment, as well as the operational costs of the reverse osmosis system, thereby increasing economic benefits.

Selection Guide:

|

|

|

|

|

|

|

|

|

|

|

|

SPRO 380-41-LD34 High Fouling Resistance |

|||||||||

|

|

|

|

|

|

|

||||

|

SPRO 365-83-34High Fouling Resistance |

|||||||||

|

|

|

|

|||||||

|

SPRO 330-120-34High Fouling Resistance |

|||||||||

|

|

|

||||||||

|

BW Series |

|||||||||

|

|

|

|

|

|

|||||

|

SW Series |

|||||||||

|

|

|

|

|||||||

|

500 |

1000 |

2000 |

5000 |

10000 |

30000 |

50000 |

80000 |

120000 |

|